Silicone combines excellent feel, reliability and long life in the most rugged environment. Silicone keypads are used in a wide range of applications including medical, industrial, instrumentation and communications equipment. While designing a new silicone rubber component or keypad it helps to use the fundamental rules of dimensioning and tolerancing, as well as some general recommendations for mechanical design. We have put together a short guide highlighting the key mechanical design considerations to help you in the process of developing silicone keypads and specialty products.

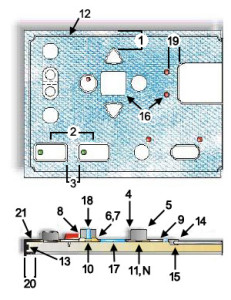

Mechanical Keypad:

- Distance of a key’s diaphragm to the edge of the keypad’s matte and any through hole is 0.040″.

- Minimum key pitch dimension is 0.080″.

- Distance between two diaphragms is 0.040″ (measured at base of diaphragm).

- The smallest blend radius of key’s side wall to top of key is 0.010″.

- Typical key taper is ³ 1° depending on key height.

- Typical chamfer dimension on a tactile keypad is 0.020″.

- Typical chamfer angle on a tactile keypad is 45.

- Clearance between a bezel to a key is 0.012″.

- Typical base (matte) thickness is 0.040″.

- Standard air channel geometry is 0.080″ to 0.125″ wide by 0.010″ to 0.013″ deep.

- Conductive contact area is 0.030″ based on keypad application and size.

- Sealing bead(s) top and/or bottom for environmental design requirements.

- Assembly aids via rattails and/or perimeter lip to hold rubber keypad to feature:

- Through hole diameter is 0.025″.

- Corner radius on matte and key’s 0.015″.

Display/ LED lightpipe/ Window opening:

- Maximum depth of undercut for feature window opening is 0.250″.

- Underside lip for window opening is the depth of undercut(#14) x 0.660″.

- Minimum size for molded in silicone window/lightpipe is 0.060″.

- Minimum thickness for molded in silicone window is 0.030″.

- Minimum height for molded in silicone lightpipe is 0.030″.

- Minimum distance from window/lightpipe to and edge is 0.030″.

- Min / Max. wrap around underside is 0.060″ to 0.500″. Deeper wraps may be considered depending on design.

- Sealing rib diameter is 0.030″.

Keypad Wrap – Around Design:

The wrap-around design offers unique capabilities in silicone rubber. Using liquid injection process, one can create hand-held units similar to complete plastic cases. With the wrap-around feature, an appealing product can be designed with all the protection requirements for harsh environments.

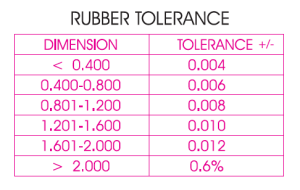

Typical Part Tolerances: