International Traffic in Arms Regulations at Si-Tech

Securing International Traffic in Arms Regulations (ITAR) compliance can have a major impact on a business. Implemented over 30 years ago by the Arms Export

Securing International Traffic in Arms Regulations (ITAR) compliance can have a major impact on a business. Implemented over 30 years ago by the Arms Export

From aerospace and military to medical and electronics, silicone products bring many benefits to all industries. Here, we will go over each market we serve

Are you a product developer? Wondering why you should partner with us for all your silicone molding needs? We have you covered when it comes

From sales support and customer visits to rapid prototyping and prompt quotes, there are many ways SiTECH supports your company and your product. We are

If you’re in the market for a custom silicone keypad that requires a tactile response, you may consider using metal domes. These domes are comprised of durable

It’s an age-old debate: silicone keypads vs. touch screens…which is better? You may have your own opinion, but in ours, we believe that silicone keypads

When determining your silicone rubber manufacturer, it is important to understand the different processes by which silicone rubber is molded. Each method comes with its

You may think you know all there is to know about liquid silicone injection molding, but we’ve compiled some facts vs. myths that may surprise

Healthcare and pharmaceutical providers of all kinds, from hospitals and doctor’s offices to laboratories and urgent care facilities, need many machines, devices and tools to

Industries Served

– Aerospace

– Industrial

– Medical

– Military

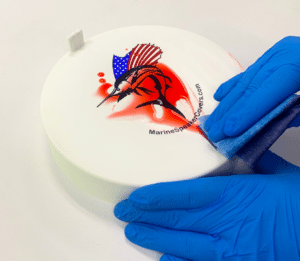

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.