When designing your new product, it is always helpful to consider the manufacturability and quality control of your product. One of the ways to help both manufacturing and quality control is to review the dimensioning and tolerancing of your product. It is important to recognize the critical features while dimensioning and tolerancing your product. These critical features are typically crucial to allowing an assembly or final product to work correctly. You should also look at how your product is dimensioned.

Important Dimensions

Dimensioning a component or product correctly allows for an improved final product or assembly. It is also a good idea to keep quality control in mind when dimensioning and tolerancing your product, by ensuring that the measurements you want can be easily obtained.

When looking for a critical feature on a design, it is important to realize that not every feature is as critical as the other. For example, when designing a silicone keypad, the distance between the keys is typically more critical than the distance of the first key from the outer edge of the part. This is mostly due to the assembly operation, where the keypad is inserted into another component.

While the outer edge distance may be important, if the keys are not positioned correctly, then the assembly will not work as intended. Typically, injection molded silicone components are more forgiving to these errors, as they are flexible, but it is a great practice to keep for all of your designs.

Critical Design Features

It is also helpful in designing to pick a critical feature to dimension off of. This means it is helpful to dimension off of something that can be found every time, on every component. An example of a bad feature to dimension off of would be theoretical centers of a component or product. Dimensioning off of a theoretical center typically leads to bad measurements and false dimensions when measuring a component or product.

On the other hand, a great way to dimension components or products is with the use of geometric dimensioning and tolerancing, or GD& T. GD& T typically requires a three-plane datum structure that can lock the part down in X, Y and Z locations. This also gives you three planes to measure off of every time.

It is important to remember, however, that dimensioning from the datum plane is not required for every dimension. Sometimes it is better to dimension between two features than to have each of those features dimension back to a datum plane. For example, when your part has a hole pattern with two or more holes, you can dimension off of the datum plane to the first hole, then off of that hole to the next. This allows the tolerancing between holes to be tighter and ensures a better fit. If you were to dimension off of the datum plane to each hole location, the distance between the holes could be significantly larger than your tolerancing allows. It is typically not a good idea to use GD& T on every dimension on a products drawing. The use of GD& T helps open up tolerancing of components when used correctly. Refer to the appropriate standards when applying GD&T to your drawings.

Quality Checks

When considering how your part is dimensioned, it is important to realize that Quality will typically be the department that measures these dimensions. With keeping Quality in mind, it is useful to dimension components and products with dimensions that can be measured. It is also helpful to Quality when you dimension components of the same family similarly. This means that if you have a new product that is similar to another product with little variations, it would be better to dimension the new product the same way you dimensioned the old version. This allows Quality to measure each part the same way every time, and helps prevent errors that could easily have been avoided.

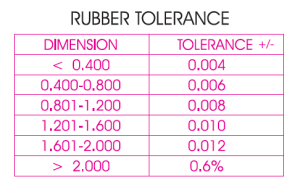

These are just a few tips to keep in mind when dimensioning and tolerancing your new injection molded silicone product.