When designing a silicone rubber keypad, it is important to consider how you want to apply force to the shorting pad, and how much force is needed. The simplest and most accurate method is by using metal domes. The use of metal domes within your keypad assembly eliminates the need for the use of a diaphragm. However, in some cases, metal domes are not able to be used. This requires the silicone rubber keypad to create the force the customer is looking for. This is where the use of Diaphragms come into play. A Diaphragm is the thin hinged area of a keypad that allows the keypad to move and flex. Diaphragms are also known as Webbing or Webs.

There are a few design recommendations we provide to our customers in regards to designing your keypad diaphragm.

Diaphragm Design Guidelines:

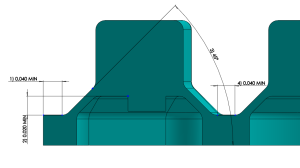

- The distance of the edge of a key’s diaphragm to the edge of the keypads mat, should be no less than 0.040”.

- The distance between two diaphragms should be no less than 0.040”.

- The minimum diaphragm height should be no less than 0.020”. Diaphragm height is typically greater than or equal to the travel of the keypad.

- The standard diaphragm angle is 45°. Modifying the angle is one way to increase or decrease the force generated by the diaphragm. A lower angle provides less force, while a larger angle increases force.

Figure 1-1

Showing #’s 1) – 4)

- The standard thickness of a keypads diaphragm is typically 0.020”. Increasing the thickness of the diaphragm increases the force required to get a tactile response.

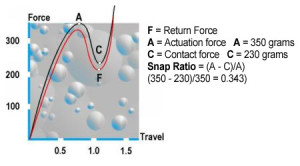

The force curve of a tactile silicone key is made up of a couple different variables. First at the top of the curve you have the actuation force. The actuation force is the force required to collapse the membrane of a silicone key. Next you have the Contact force. The contact force is the amount of force required to maintain the closure of the silicone key. With these two forces, you are able to calculate a snap ratio. The formula for determining the snap ratio as followed: (Actuation Force – Contact Force) / Actuation Force. This ratio is what gives the keypad a tactile response or more simply put the snap feeling. The last force to determine is the return force. This is the force created by the keypad’s webbing as it returns to its neutral position. These forces are all mostly determined by the design of the webbing. Different variations in the thickness, angle and travel will give different forces across the board.

Figure 1-2