SiTECH Industries: Military

We are proud to partner with branches of the military to best serve their rubber keypad and component needs. We understand how important quality, durable

We are proud to partner with branches of the military to best serve their rubber keypad and component needs. We understand how important quality, durable

In short, accessibility improves usability. That’s why we ensure all our keypads are made with the end user in mind. If it’s not easy to

Today, we’ll go over the importance of considering technicians when designing a keypad. Remember, it’s not just about the user! Designing custom silicone keypads takes

The creation of a more profitable product is one of the main goals of any business owner. There are many ways you can prioritize profitability,

The creation of a more profitable product is one of the main goals of any business owner. There are many ways you can prioritize profitability,

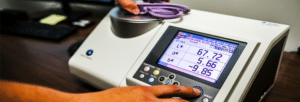

The creation of keypads isn’t something that can be done in a bubble. It needs to be put through the rigors of actual work environments

The creation of keypads isn’t something that can be done in a bubble. It needs to be put through the rigors of actual work environments

When on the hunt for the highest quality military rubber keypads and components, SiTECH can deliver on promises of excellence to your industry. Our silicone

We’re all about coatings here at Si-Tech. In fact, we use a total of four main types when it comes to industrial coatings. They’re each

Industries Served

– Aerospace

– Industrial

– Medical

– Military

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.