5 Reasons Why Silicone Keypads Are Preferred Over Touchscreens

From responsiveness to accuracy, there are many reasons why silicone keypads are preferable over touchscreens. Yes, touchscreens seem to be the most popular option right

From responsiveness to accuracy, there are many reasons why silicone keypads are preferable over touchscreens. Yes, touchscreens seem to be the most popular option right

Ah let us count the ways! From our vast experience (75+ years!) to the quality of our silicone products, you can bet we offer the

A prototype is an early model, sample, or release of a product that is created to test a process or a concept. Put another way,

You probably don’t give much thought to how your device’s keypad is made and assembled, but it’s a pretty cool process. We know because we

We are very proud of our capabilities here at SiTECH, where we demand excellence out of every product we produce. Our rapid prototyping, liquid injection

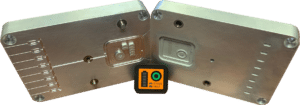

Mold design and silicone parts go hand in hand. One affects the other, which means resulting quality is highly dependent on how the other functions.

Coatings for the keypads we manufacture are critical in ensuring usability, longevity and comfort. From low-cost design and fast scalability to low-contact resistance and ease

If you’re in the military, automotive or similar industry, your immediate environment is pretty unpredictable. Unlike a controlled environment like an office, you need equipment

Many people are in one of two camps: they either prefer silicone keypads or they prefer touch screens. But we’re here to tell you why

Industries Served

– Aerospace

– Industrial

– Medical

– Military

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.