Decorating Considerations

Decoration is important not just in home design and cookies, but in silicone keypads as well! We are well-versed in decorating our silicone injection molding

Decoration is important not just in home design and cookies, but in silicone keypads as well! We are well-versed in decorating our silicone injection molding

ITAR compliance is a critical step in the manufacturing process. Without it, you could be at risk of violating federal law. SiTech operates its manufacturing

It can be helpful to know about the materials and processes we use here at SiTech as you prepare for your journey with us. That’s

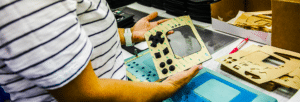

When choosing a silicone keypad company, you want one that’s versatile and that can meet the demands of your product no matter what. Here at

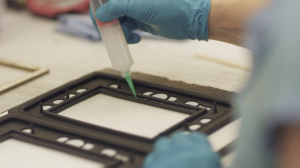

Known for short as LIM, liquid injection molding is a process we use here at SiTech to craft parts, keypads and components with the highest

You may not be aware of what ITAR compliance is, and that’s OK. It’s more important that we know what it means and do our

Knowing the materials that comprise your molded silicone keypads is a big part of the educational process with our clients. We want you to be

Rapid prototyping – something we offer here at SiTech – is desirable for many reasons, not the least of which is that it can increase

Customer satisfaction is everything. At least that’s what we think of things here at SiTech. Today we’ll talk about how collaborating with your client results

Industries Served

– Aerospace

– Industrial

– Medical

– Military

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.