Understanding REACH Compliance and Its Importance in the Silicone Industry

Understanding REACH Compliance and Its Importance in the Silicone Industry In the world of manufacturing, particularly in sectors involving chemicals and materials, regulatory compliance is

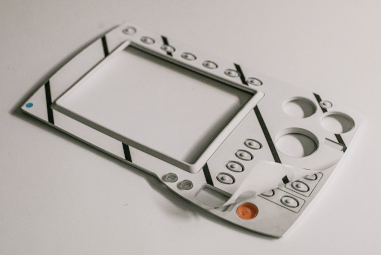

Si Coat™ is an abrasion resistant coating system developed by SiTECH Corp. for use in silicone rubber applications requiring superior wear protection.

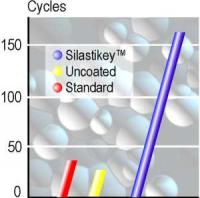

Si Coat ™ is a tough, wear-resistant coating offering an outstanding abrasion resistance for elastomer keypad applications. Under independent lab test using an RCA abrasion wear tester, Si Coat I surpassed by more than 20 times the standard acceptance criteria for the keyboard/keypad industry. Now, you can be sure that the SiTECH’s rubber keypad will have the same consistent look and feel with no degradation throughout the life expectancy of your product.

When combining Si Coat I ™ with our proprietary screened silicone inks and Liquid Injection Molding, we offer you a unique set of features that will assure the right solution for your product requirements.

Si Coat I offers:

Si Coat™ is an abrasion resistant coating system developed by SiTECH Corp. for use in silicone rubber applications requiring superior wear protection.

Si Coat ™ is a tough, wear-resistant coating offering an outstanding abrasion resistance for elastomer keypad applications. Under independent lab test using an RCA abrasion wear tester, Si Coat I surpassed by more than 20 times the standard acceptance criteria for the keyboard/keypad industry. Now, you can be sure that the SiTECH’s rubber keypad will have the same consistent look and feel with no degradation throughout the life expectancy of your product.

When combining Si Coat I ™ with our proprietary screened silicone inks and Liquid Injection Molding, we offer you a unique set of features that will assure the right solution for your product requirements.

Si Coat I offers:

SiCoat V ™ is a proprietary conductive silicone based coating developed by SiTECH Corp. for use in silicone keypad applications.

SiCoat V ™ is a proprietary conductive silicone based coating developed by SiTECH Corp. for use in silicone keypad applications.