When designing a silicone rubber keypad, it is important to consider how you want to apply force to the shorting pad, and how much force will be needed. This can be accomplished through the design of the key itself, and the implementation of tactile switches or metal dome switches placed under the key. It’s also important to understand what forces are at play, and how these forces can be established and altered.

The force curve of a tactile silicone key is made of a couple different variables. First is the “actuation force”. A key will typically be surrounded by a diaphragm, also known as webbing or webs. This is the thin hinged area of a keypad that allows the keypad to move and flex. The actuation force is the force required to collapse the diaphragm of a silicone key. Next is the “touch force”. The touch force is the amount of force required to keep the key compressed. With these two forces, you are able to calculate what’s known as a snap ratio. This ratio is what gives the keypad a tactile response, or more simply put, the “snap” or “click” feeling. The last force to determine is the return force. This is the force created by the keypad’s webbing as it returns to its neutral position. These forces are all mostly determined by the design of the diaphragm. Different variations in the thickness, angle and travel will give different forces across the board. The typical design standards are as follows:

- The distance of the edge of a key’s diaphragm to the edge of the keypad mat should be greater than 0.040”.

- The distance between two diaphragms should be no less than 0.040”.

- The minimum diaphragm height should be greater than 0.020”. Diaphragm height is typically greater than or equal to the travel of the keypad.

- The standard diaphragm angle is 45°. Modifying the angle is one way to increase or decrease the force generated by the diaphragm. A lower angle provides less force, while a larger angle increases force.

- The standard thickness of a keypads diaphragm is typically 0.020”. Increasing the thickness of the diaphragm increases the force required to get a tactile response.

When designing your silicone rubber keypad, there are three main types of keys to consider. First you need to determine whether or not you will be using metal domes, tact switches, or shorting the pad via an electrical source on the silicone key itself. You must then determine whether or not you wish the keypad to be tactile. A good example would be a button on a television remote control versus a microwave oven. Typically, when a remote control key is pressed, the user will experience a familiar “snap”, while most microwave ovens have no “snap” when a button is pressed.

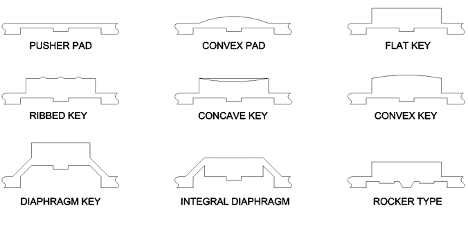

When silicone keypad assemblies utilize metal domes or tact switches, it is preferred to use the “pusher pad” design of silicone keys. This keypad design utilizes what we call a “dead web” which is simply a flat diaphragm used to prevent a double click feeling from occurring. The height of the metal dome or tact switch determines the height of the contact surface on the bottom of the key. Typically, we recommend a 0.005” of preload onto the dome or switch to minimize the distance the key has to travel and to keep the force profile as close to that of the dome or switch as possible.

If the key itself is to provide the tactile feedback, then an angled diaphragm will be needed. There are many different variations of diaphragms but the general function remains the same. Typically a conductive material is molded into the silicone key which provides the means to short the pad on the circuit.

Another type of key design is what we at Si-Tech call a “rocker type”. The rocker type of key is designed to incorporate multiple shorting pads within one key. An example would be if you wanted to have an object move forward and backwards with one key, if you were to press on one side of the key, one of the shorting pads would short, and vice versa. This is made possible by incorporating a pivot feature within the middle of the key. These keys typically do not have a high snap, but can be utilized in the pusher pad or tactile types of keys.

Below are a few of the different types of keys we frequently see here at Si-Tech: