Accessible Custom Silicone Keypads: Increasing Equipment Usability

Making things easy on your users is a key component in keypad and device design. If your equipment is not easy to use, there’s no

Making things easy on your users is a key component in keypad and device design. If your equipment is not easy to use, there’s no

Because our products are used for military applications, we need to take certain precautions in the creation of our silicone keypad production processes. ITAR is

When choosing a company to manufacture your keypads, you understandably want to know all you can about the company and its capabilities. We know that,

What does it mean to decorate, in terms of silicone injection molding for keypads and other products? Let’s go over our graphic design process and

One of our specialty industries involves aerospace applications of SiTECH’s silicone liquid injection molding. Liquid injection molding, or LIM for short, is an industrial fabrication

Interested in designing your own silicone keypads? Thankfully, we here at Si-Tech specialize in customizing keypads for a variety of industries, with capabilities ranging from

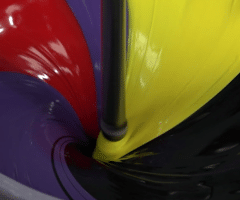

Color matching is important in the world of silicone keypad manufacturing. That’s why SiTECH goes above and beyond to precisely match the exact color for

We are nothing if not versatile here at SiTECH Corp.! Our silicone products aren’t just manufactured with one particular industry in mind. Rather, we supply

From rapid prototyping and liquid injection molding to design and color matching, SiTECH is skilled in many capabilities that add value to our clients. Let’s

Industries Served

– Aerospace

– Industrial

– Medical

– Military

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.